Applying new materials and methods to help amputees

2022 IDSA IDEA Award Finalist

First Place Thesis, UH Industrial Design 2021

Featured at the 2021 Applied Human Factors and Ergonomics Conference

The prevalence of limb loss in the US is expected to double by 2050, further increasing the number of amputees living at or below the poverty line. Many of these amputees are unable to access commercial upper-limb prostheses, which range from $10,000 for cable actuated models to over $100,000 for advanced brain-controlled hands. As a result, amputees are forced to depend on family and friends, crowdfunding campaigns, or improvised prosthetics.

How do current designs fail to meet user needs?

3D printing offers a way to make functional prostheses at low cost. However, current designs suffer from functionality issues which render them impractical in real-world applications. Without a satisfactory open-source solution, occupational therapists fashion improvised prosthetics from hardware store materials.

Designing with, not just for, stakeholders

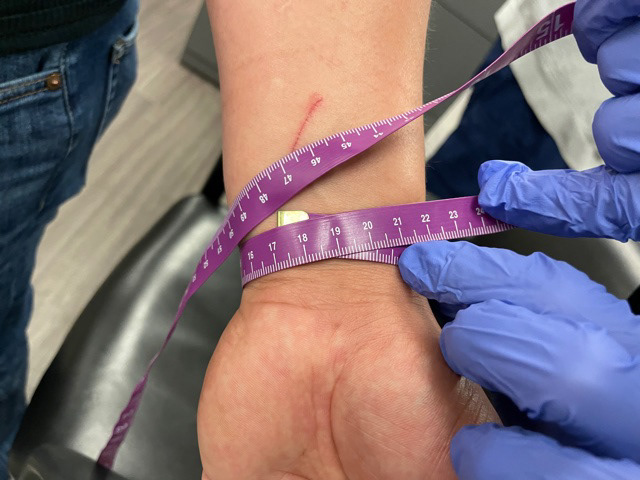

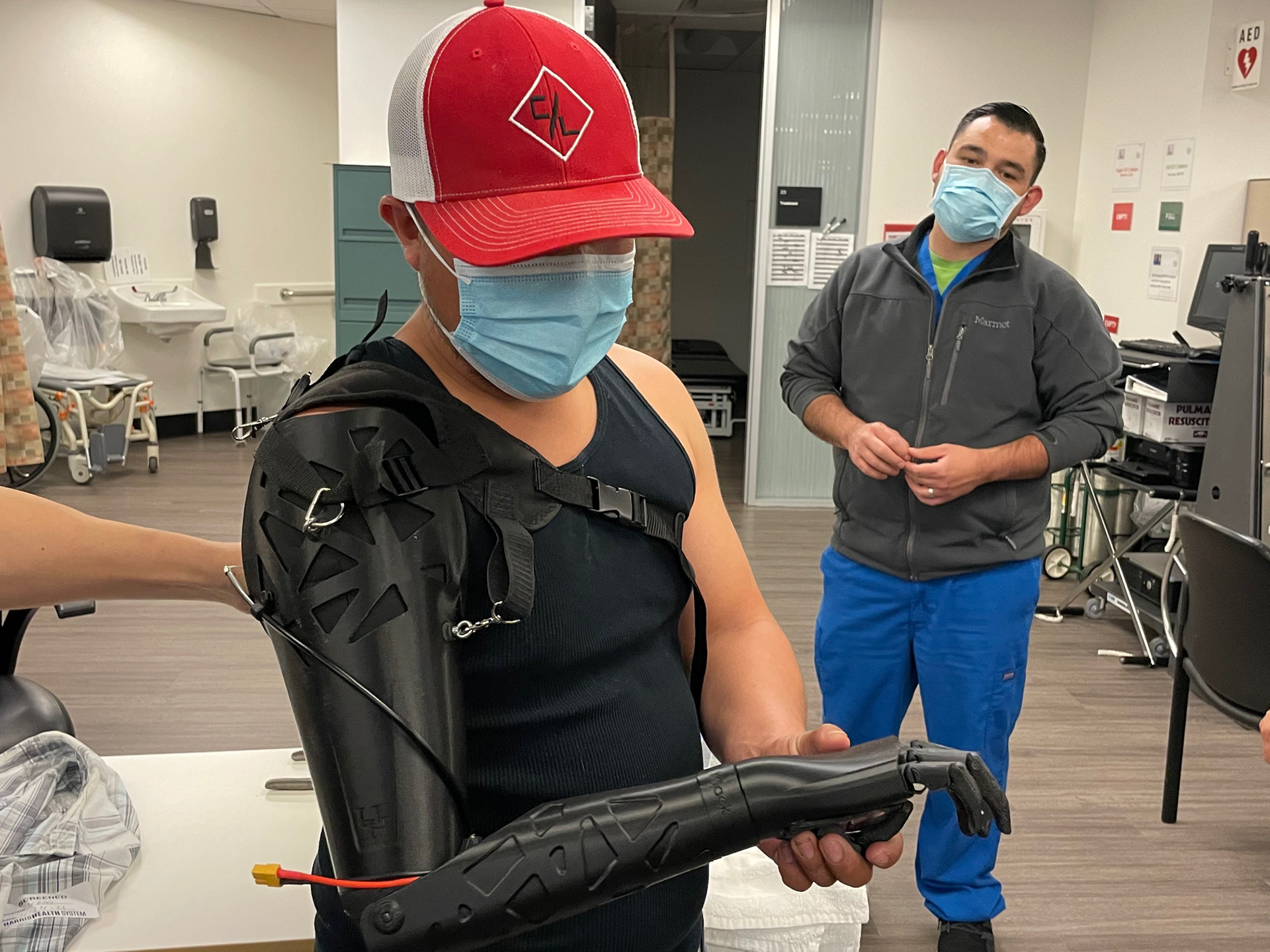

With guidance from occupational therapists in the Harris Health System's Quentin Mease Community Hospital, Knack was fitted to an amputee patient in need of a prosthesis. This dialogue was valuable to fully understand the demands of day-to-day wear. Over four separate visits, fit and function of the arm assembly was refined.

Exploring compliant design methods

While most currently available open-source prosthetic hands are limited by their rigid construction, Knack applies 3D-printed thermoplastic polyurethane (TPU) to achieve greater ability and realism with reduced weight and part count. The prototyping process centered on refining the compliant mechanism of each finger.

Built for the real world

To ensure durability for the end user, Knack's rigid components were printed on a MarkForged Mark II 3D Printer from Onyx filament, a nylon/carbon-fiber composite material. Each finger is an easily replaceable modular unit that snaps into the base.

Project outcome and next steps

On conclusion of the project, Knack was given to the amputee stakeholder for his personal use. While improvements are planned for future versions, Knack successfully demonstrates the potential of a compliant, modular design to improve the fabrication, fitting, and performance of an affordable prosthetic hand.

The research paper accompanying the project was featured at the 2021 Applied Human Factors and Ergonomics Conference and published in the conference journal by Springer Nature. Knack was also featured at the 2021 Conference of the Rehabilitation Engineering and Assistive Technology Society of North America.